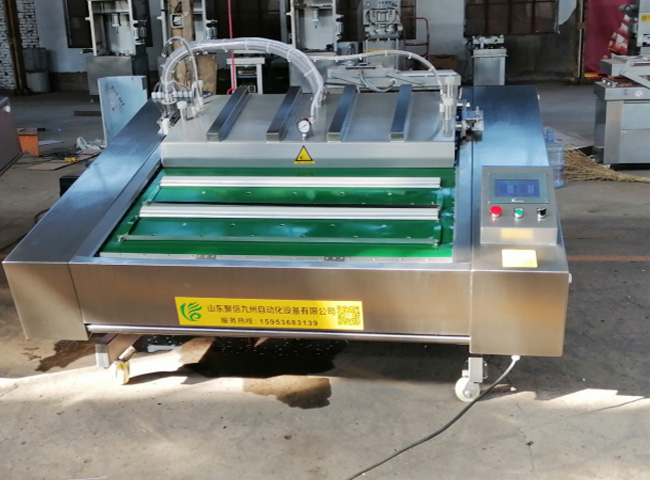

Working mechanism:

The main function of a rolling vacuum packaging machine is to remove oxygen, which is beneficial for preventing food spoilage. Its principle is also relatively simple, because food spoilage is mainly caused by the activity of microorganisms, and the survival of most microorganisms (such as mold and yeast) requires oxygen. Vacuum packaging is based on the principle of movement, which extracts oxygen from the packaging bag and food cells, causing microorganisms to lose their living environment.

Equipment usage:

Rolling vacuum packaging machine is used for various plastic composite film bags or aluminum foil composite film bags, to vacuum (inflate) package various solid, powdered objects, liquids such as raw and cooked foods, fruits, local specialties, medicinal materials, chemicals, clothing, hardware products, electronic components, etc. Especially suitable for vacuum packaging of larger objects.

Equipment characteristics:

(1) The computer control adopts Mitsubishi PLC from Japan, which has reliable performance;

(2) Fully computerized touch screen automated control, simple and easy to operate;

(3) The operating system is fully sealed and the entire machine can be rinsed with clean water;

(4) The whole machine can tilt at 4 different angles to meet various packaging requirements;

(5) Rolling continuous packaging improves work efficiency.

Equipment advantages:

(1) The vacuum pump adopts the original German BUSCH vacuum pump, which is currently the best vacuum pump in the food vacuum packaging machine industry and can be used continuously for a long time;

(2) All made of 304 stainless steel, the studio and countertop have excellent rust and corrosion resistance. The Dutch strip and the 8mm thick 304 stainless steel have good resistance to intergranular corrosion, and can be used for a long time without deformation or air leakage, meeting the hygiene requirements.

(3) Fully automatic and semi-automatic can be switched, with simple and convenient operation, high sealing efficiency, and can be used more than 300 times per hour.

(4) The sealing length is 1100mm, and the two heating strips are arranged neatly and symmetrically, resulting in better sealing effect. It can be used to heat and seal composite films such as aluminum foil and plastic film.

(5) The operating system is fully sealed and the entire machine can be rinsed with clean water.

(6) The vacuum chamber has good sealing performance and a low pressure strength of up to 1.3332Kpa

(7) The appearance design is beautiful and elegant, the structure is reasonable, and the overall performance of the machine has exceeded similar foreign products

-

Electric heating deep fryerAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More

Electric heating deep fryerAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More -

Fried round potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More

Fried round potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More -

Fried assembly lineThis production line is equipped with an automatic oil temperature control systemView More

Fried assembly lineThis production line is equipped with an automatic oil temperature control systemView More -

Fried square potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More

Fried square potAdvanced oil-water integration technology overcomes the shortcomings of conventional frying machinesView More